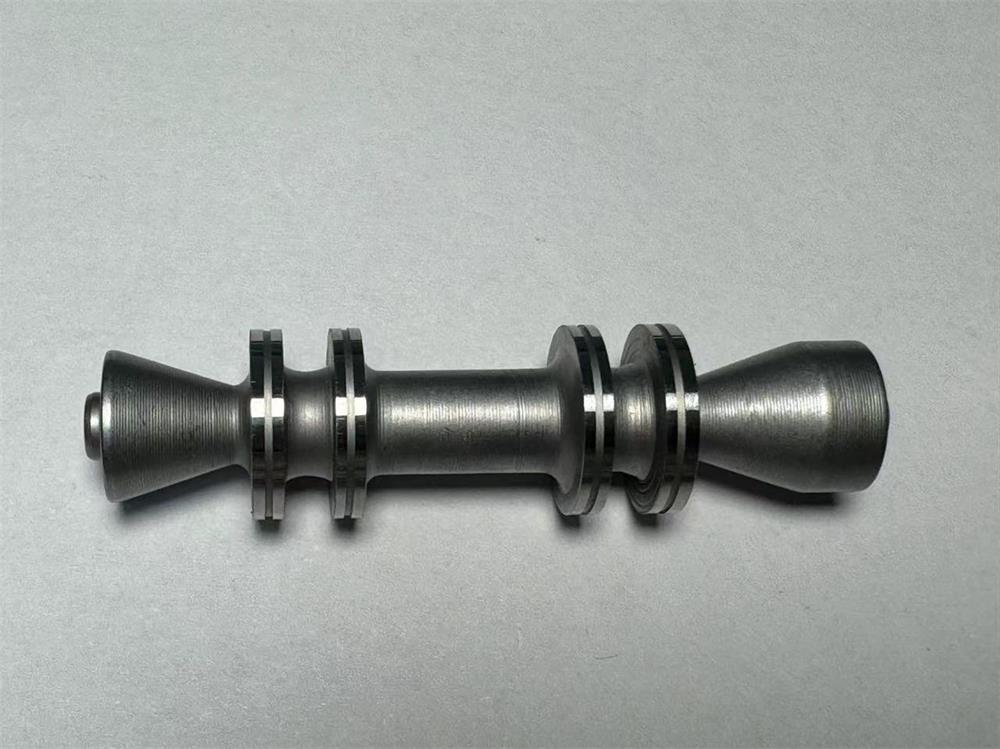

Project Quantity

400pcs

We made the mould first and made a few samples first. Our client was very satisfied with our product quality after receipt of the samples, then begin 400pcs batch order production.

Project Process

Copper centrifugal casting + Machining

Custom Copper Bushing Material

C86200

Application

Marine use

Technical Requirement

Size and chamfer with tolerance: complete meet the drawing requirement

Surface finishing: RA1.6 in inner diameter, RA6.3 in outer diameter

Material: the material composition and the mechanical property could fully meet the standard of C86200.

Need SGS inspection before delivery.

SGS On-site Inspection

SGS come to our factory to do the final inspection before shipment.

Size Inspection

Champer Inspection

Surface Finishing Inspection

The surface finishing is 1.471RA, our required is 6.3RA.

The inner finishing is 1.050RB, our required is 1.6RA.

Our smoothness is much better than the drawing required.

Packing

We use a export non-wood carton to pack it.

Along with the shipment, we also send a test circle for our clients to do the material check, verify the material and the strength, etc.