N04400 nickel-copper alloy, mainly containing nickel and copper, with a small amount of other elements, has high corrosion resistance, mechanical strength and ductility, and is suitable for chemical, marine engineering, aerospace and food processing industries.

N04400 is a nickel-copper alloy material, also known as Monel 400. It is mainly composed of high-purity nickel and copper and contains small amounts of elements such as iron, manganese, silicon, titanium, aluminium, carbon, sulfur and phosphorus.

Chemical Composition

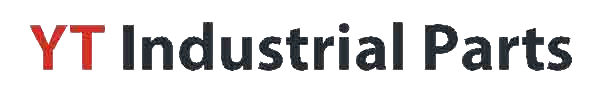

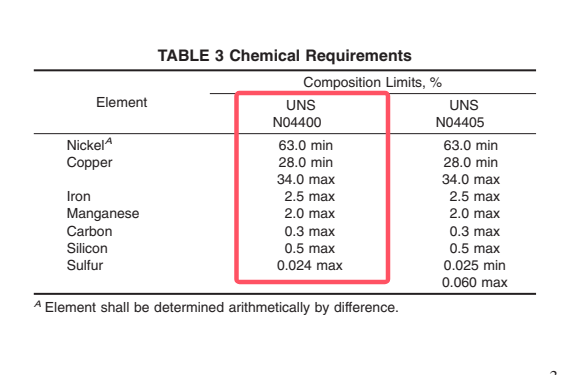

The chemical composition of N04400 alloy mainly includes nickel (Ni), copper (Cu) and a small amount of other elements. The specific composition ratios are as follows:

Nickel (Ni): 63.0% minimum, one of the main components of the alloy, has an important influence on the corrosion resistance and mechanical properties of the alloy.

Copper (Cu): 28% minimum to 34% maximum, another important component of the alloy, together with nickel, determines the basic properties of the alloy.

Other elements such as iron (Fe), manganese (Mn), carbon (C), silicon (Si), phosphorus (P) and sulfur (S) also have strict content limits, such as the maximum content of iron is 2.5%, the maximum content of manganese is 2.0%, the maximum content of carbon is 0.3%, the maximum content of silicon is 0.5%, and the maximum content of sulfur is 0.024%.

Precise control of these elements helps ensure the stability and consistency of the alloy.

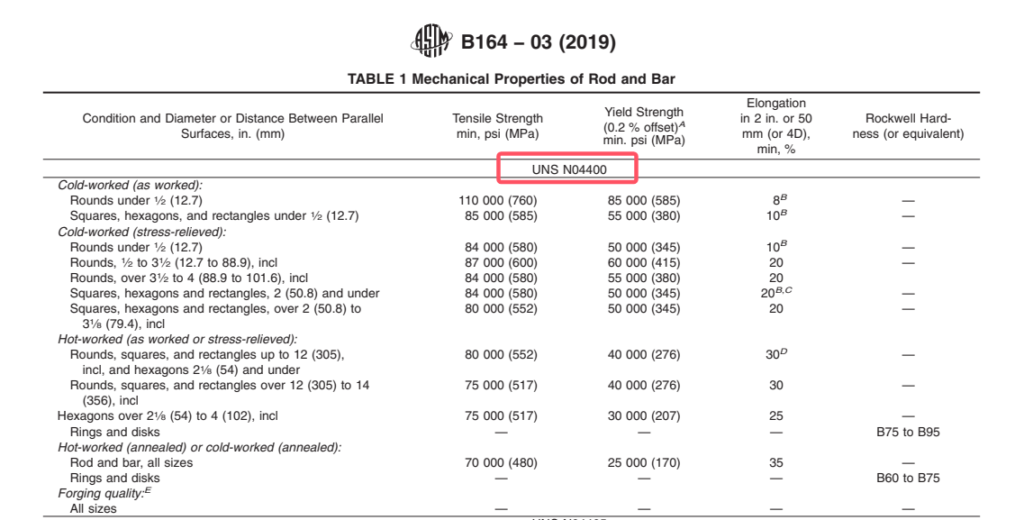

Physical and mechanical properties

N04400 alloy has a series of excellent physical and mechanical properties, including:

Density: about 8.83 g/cm³, which makes it have high density and weight.

Melting point: about 1300-1350 ℃, indicating that the alloy can still maintain stability at high temperatures.

Thermal conductivity: about 13.4 W/(m·K) (some data indicate 21.8 W/m·K), indicating that the alloy has good thermal conductivity.

Linear expansion coefficient: about 13.9 μm/m·K (some data indicate 13.3 x 10^-6/degree Celsius), which means that when the temperature changes, the length of the alloy will change accordingly.

Elastic modulus: about 179 GPa, indicating that the alloy has a certain elasticity and can return to its original shape after being subjected to force.

Regarding mechanical properties, the tensile strength σb of N04400 alloy is ≥480 MPa, the yield strength σb is ≥195 MPa, the elongation δ is ≥35%, and the hardness is HB 135-179. These properties enable the alloy to exhibit good strength and toughness when subjected to load.

Characteristics

N04400 alloy has the following main characteristics:

Excellent corrosion resistance: The alloy performs well in harsh environments such as seawater, salt water, various acids (such as hydrofluoric acid, and sulfuric acid) and chemical solvents, and can maintain good performance even under high temperatures and pressure.

Good mechanical strength and ductility: N04400 alloy has excellent corner bending performance and can maintain high strength and stiffness even under extreme temperatures and pressures.

Thermal stability: It can be used for a long time at high temperatures without deformation or fracture.

Good resistance to thermal expansion: When the temperature changes, it will not produce excessive stress due to thermal expansion.

Application Areas

Due to the excellent properties of N04400 alloy, it is widely used in many fields, including:

Chemical and petrochemical: used to manufacture heat exchange equipment, boiler feed water heaters, pipelines, containers, towers, tanks, valves, pumps, reactors, etc.

Marine engineering: used for marine crude oil extraction, diving equipment, offshore oil platforms, etc.

Aerospace industry: used to manufacture jet engines, aerospace devices, etc.

Food processing industry: used for saltwater treatment and food processing equipment, etc.

In summary, N04400 is a nickel-copper alloy with excellent corrosion resistance and high-temperature performance, which plays an important role in many industrial fields.