General Description

FRP stands for Fiber Reinforced Plastic, and FRP grating refers to a type of grating made from composite materials, typically consisting of a matrix of resin reinforced with fiberglass or other fibers. FRP grating offers several advantages over traditional materials such as steel, including corrosion resistance, lightweight, high strength, and low maintenance requirements. It is commonly used in applications where durability, safety, and resistance to chemicals or harsh environments are important, such as industrial platforms, walkways, stair treads, and various structural components.

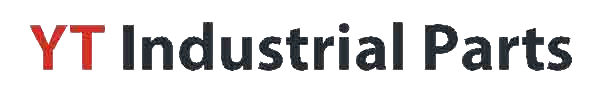

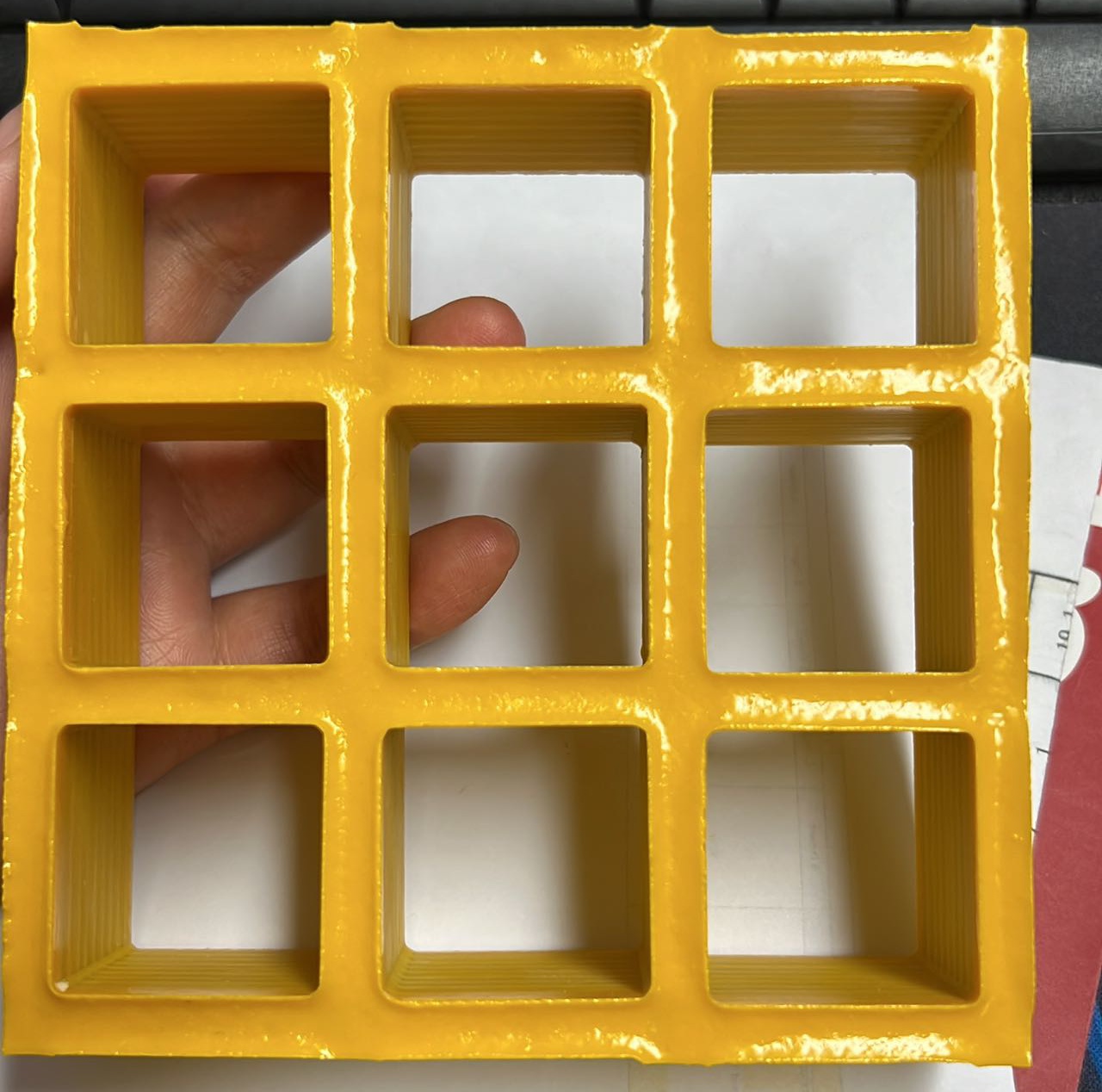

Style of FRP Grating

Glass Fiber reinforced plastic (FRP) molded grating is made of interlaced weaving of glass fibers, resin pouring and molded as a whole. The glass fiber-reinforced plastic grille plate with many regularly distributed rectangular and square spaces has bidirectional isotropic mechanical characteristics.

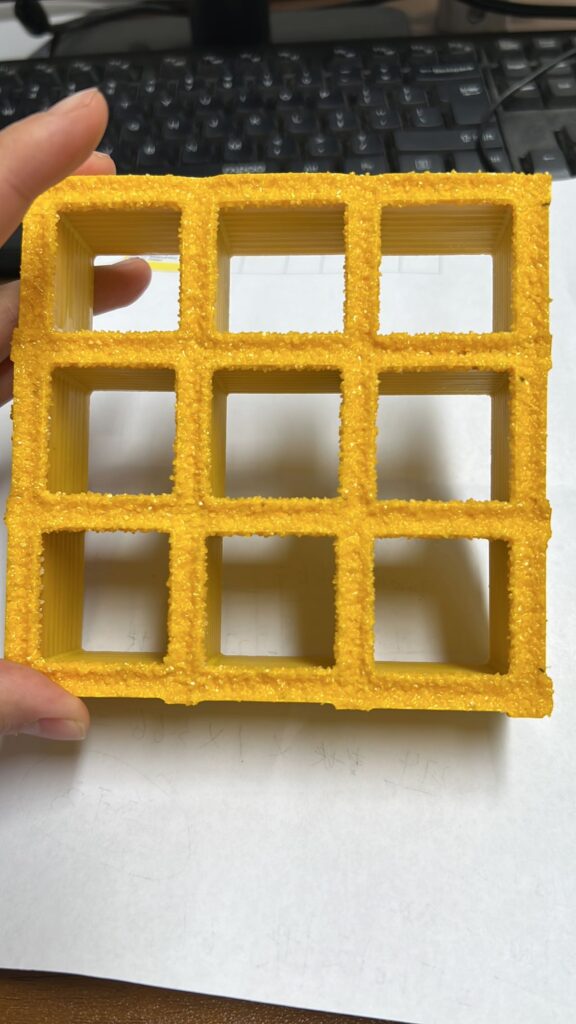

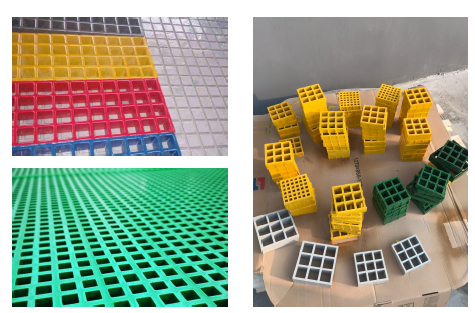

More pictures

Application

It is widely used in the petroleum, chemical industry, electric power, paper industry, printing and dyeing, electroplating, ocean exploration, sewage treatment and other industries. Such as working platforms, equipment platforms, drilling platforms, and walkway lights. It is an ideal product in a corrosive environment, and it is also suitable for civil buildings in the facility.

Raw Material Resin Style

| Resin Style | Resin Matrix | Performance | Flame Retardant Rate | Maximum Temperature |

| Type VE | Vinyl Type | It has excellent corrosion resistance and can withstand harsh corrosive environments such as acid, alkali, solvent or acid-base alternation. | Class 1 flame retardant, flame spread index less than 10. | 230°F/110℃ |

| Type 1 | Isophthalic Resin | It has excellent corrosion resistance, and can withstand environments such as medium-concentration inorganic acids, alkalis and various salts. | Class I flame retardant, flame spread index less than 25. | 221°F/105℃ |

| Type F | Food Grade Resin | Isophthalic food-grade resin has good corrosion resistance as isophthalic resin. | Class I flame retardant, flame spread index less than 30. | 221°F/105℃ |

| Type 0 | Ortho-Phthalic Resin | It has general corrosion resistance and can withstand seawater, weak acid and atmospheric aging environment. | Class I flame retardant, flame spread index less than 25. | 212°F/100℃ |

Type 1 is often used in environments with strong acid corrosion or general alkaline corrosion;

Type F is commonly used in meat products, food processing and water plants;

Type 0 is often used in general corrosive environments, weak alkali corrosion and atmospheric ageing environment.

Raw Material-Fiberglass Style

| Fiberglass type | Fibreglass type | Performance |

| E | E-glass fibre | High strength, strong corrosion resistance |

| ATH | E-glass fiber | E-glass fibre |

Molded FPR Grating Properties

Anti-Corrosion

Molded grating has very superior corrosion resistance to acids, alkalis, organic solvents, salts and many other gas and liquid media, and has incomparable advantages in the field of anti-corrosion. According to the requirements of the actual place of use, o-phthalic, isophthalic, and vinyl resins can be economically selected as matrix materials.

Anti-Fire

The formula designed by our YT company can meet the fire prevention requirements of the engineering team, so as to ensure safety. The company has passed American ASTM-E84 and

ASTM-E119 flame retardant test, with good flame retardant and fireproof performance.

Anti-Shock and Anti-Fatigue

Molded grating has high impact strength and allows repeated stress without permanent deformation, while metal grating retains permanent deformation after impact and requires repair. The molded grille has moderate elasticity, which makes the personnel who work on it feel comfortable for a long time, reduces the sense of urgency on the legs and back of the staff, reduces the occurrence of accidents caused by it, and is conducive to improving production efficiency.

Lightweight, high strength, easy to cut and install

Because it is made of resin and glass fiber, its density is low, not more than 2 kilograms per cubic meter, which is only 1/4 of steel and 2/3 of aluminum. Its strength is 10 times that of polyvinyl chloride, and its absolute strength exceeds the level of aluminum and ordinary steel. Its lightweight can greatly reduce the foundation support, thereby reducing the material cost of the project. The molded grille is easy to cut, does not require large lifting equipment, and only requires a small amount of labor and electric tools, which greatly reduces the installation cost and is usually produced in the form of a whole board. When the customer needs a small size grid plate, it can be realized by cutting. Cut and process the grid reasonably according to the size and installation requirements, in order to maximize the economic benefits without affecting the intrinsic performance of the grid. The cut section is processed with a resin coating to ensure that its corrosion resistance is not affected. This material can also be ground, and drilled, but not turned and tapped. Arbitrary cutting will not change the mechanical properties of the molded grille, nor will it cause falling apart or other consequences.

Anti-skid

The molded grating has anti-slip function. The molded FRP grating has two types of naturally formed anti-slip crescent surface and anti-slip sand. The anti-slip sand surface is also molded with sand in the mold and processed again by adhesive There are two types of sanding, both of which provide excellent anti-skid performance, the sand layer is not easy to fall off, and is durable.

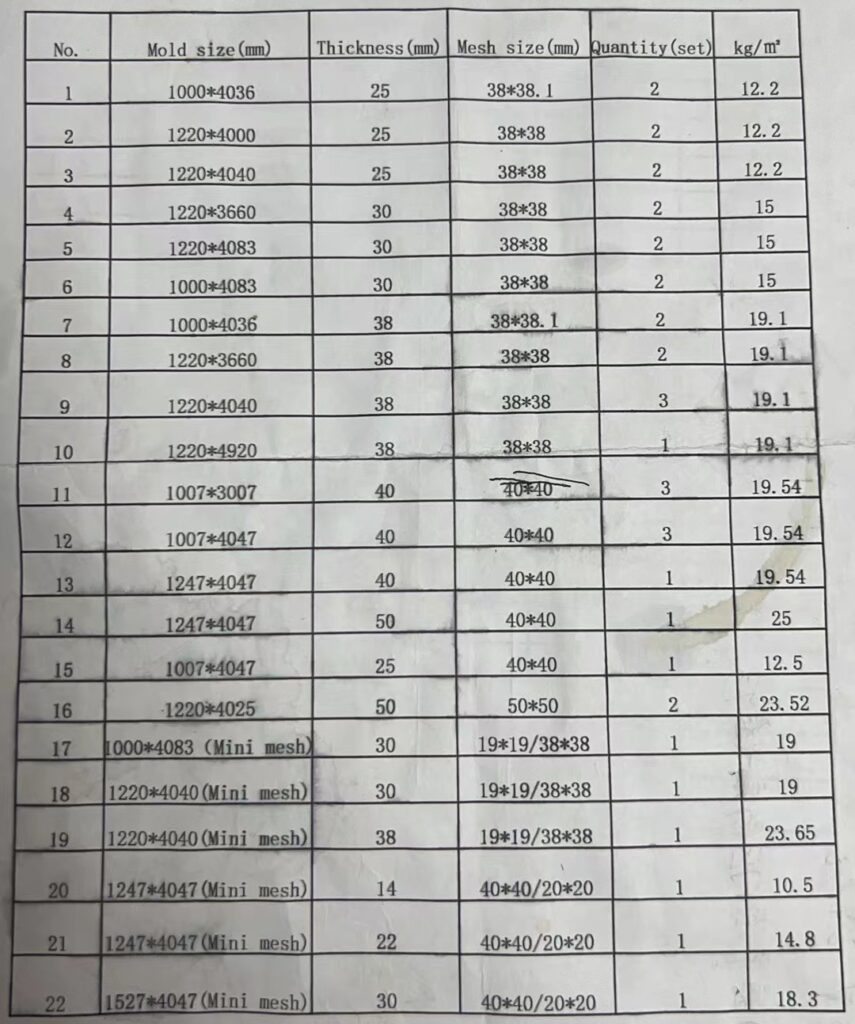

Mould Size of FRP Grating

Ask for an inquiry now!

Email: sales@yutungindustrial.com