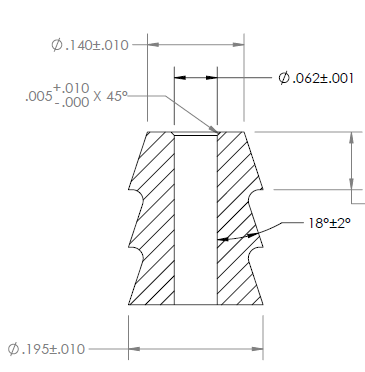

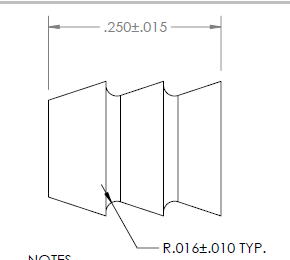

Drawing

Material

This part is made of POM material, anti-UV.

Polyformaldehyde(POM), is a kind of plastic.

It is another engineering plastic with excellent comprehensive properties after polyamide. It has high mechanical properties, such as strength, modulus, wear resistance, toughness, fatigue resistance and creep resistance. It also has excellent electrical insulation, solvent resistance and processability. It is one of the five general-purpose engineering plastics.

Process

This is the plastic injection moulding process. We make the parts by customs drawing with quantity.

Before production, we will study clients’ drawings, and check our equipment to see if it is within our production ability scope. If there are problems with the production process, we will discuss them with clients to find a good solution. Sometimes clients design the parts in the office which is not suitable for production. So after all is determined, we will make a final drawing to our clients for approval before the order.

Our common materials for the plastic injection moulding process are PE, PP, ABS, PPS, PA+GF30, PBT, TPU and TPE elastomer etc.

Packing

This order quantity commonly is more than ten thousand. It is a small part, so we will use a sealed plastic bag to pack it, and then use a carton outside.

It will be shipped by ocean together with other items.