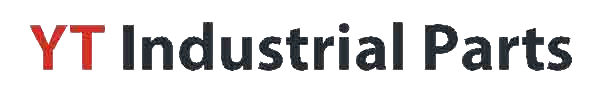

Process

Powder metallurgy

Project Description

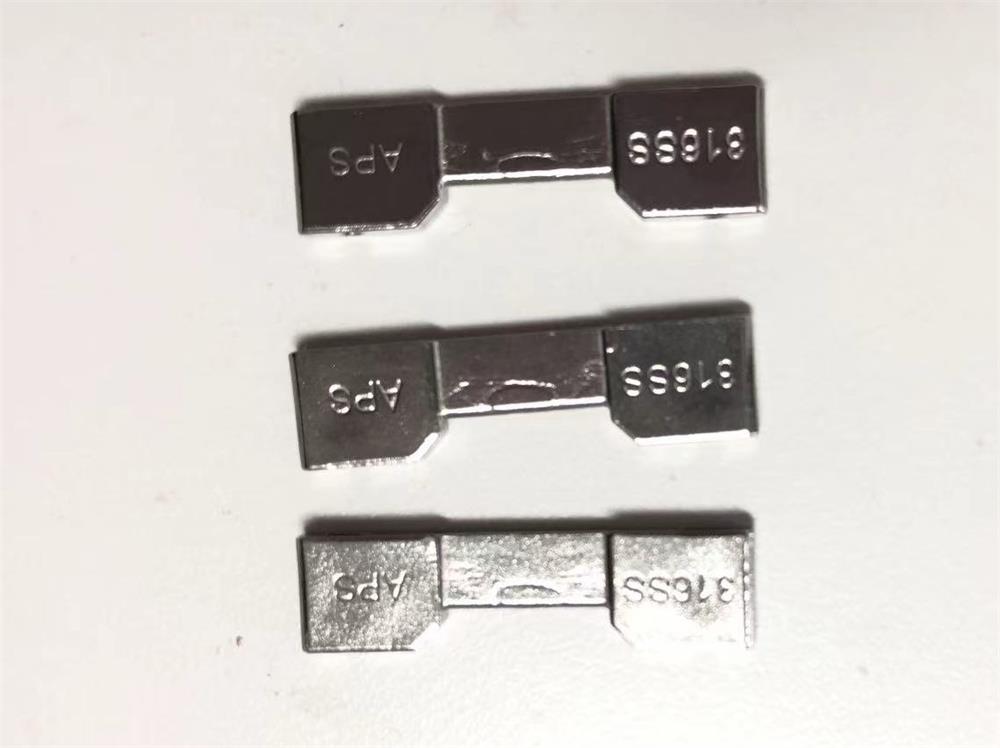

It is a repeated order, commonly will order 10000pcs for one batch. It is made of stainless steel.

Keywords Related to Stainless Steel Sintering

Stainless steel

Refers to a group of corrosion-resistant steel alloys that contain a minimum of 10.5% chromium by mass.

Sintering

A manufacturing process that involves compacting and heating powdered materials to form a solid object without melting them completely. In the context of stainless steel, sintering involves the consolidation of stainless steel powders into a solid mass.

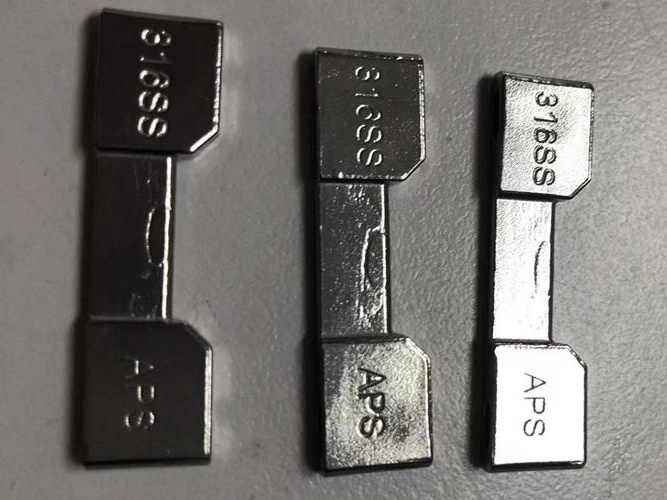

Powder metallurgy

A field of materials processing that deals with the production of components from metal powders. Stainless steel sintering is a common technique used in powder metallurgy.

Sintering temperature

The specific temperature at which the stainless steel powder is heated during the sintering process. This temperature is critical in achieving proper densification and bonding of the particles.

Sintering atmosphere

The environment in which the sintering process takes place. It can be controlled to optimize the sintering process and prevent oxidation or contamination of the stainless steel.

Sintering time

The duration for which the stainless steel powder is held at the sintering temperature. It affects the densification and mechanical properties of the sintered stainless steel.

Sintering furnace

The equipment used to heat and maintain the sintering temperature during the process. It provides the necessary controlled atmosphere and heating conditions.

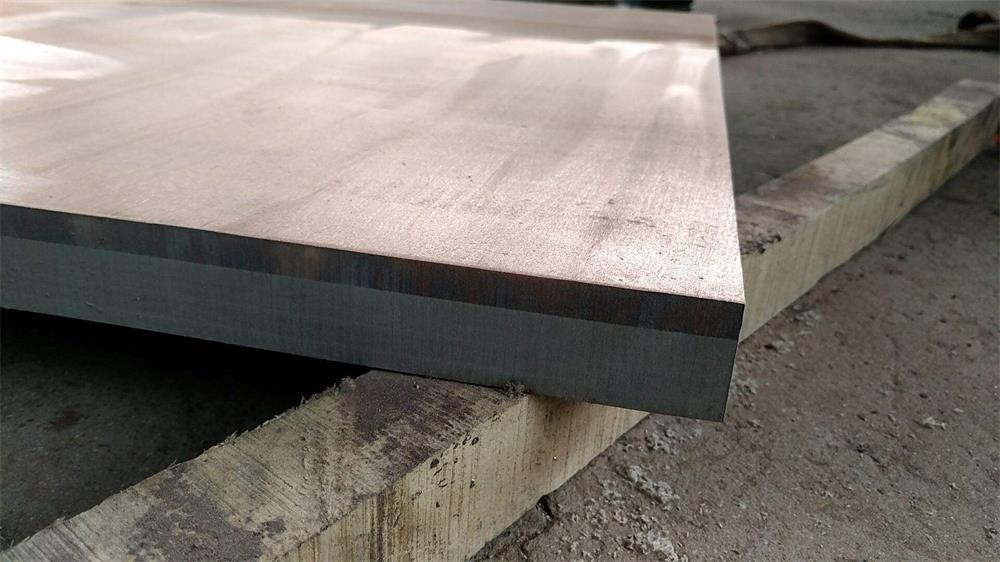

Sintered stainless steel properties

Refers to the physical, mechanical, and chemical properties of the final product obtained through the sintering process. These properties include density, strength, hardness, corrosion resistance, and dimensional stability.