Project Data: Sep 2022

Project country: New Zealand

Product characteristics and production difficulty:

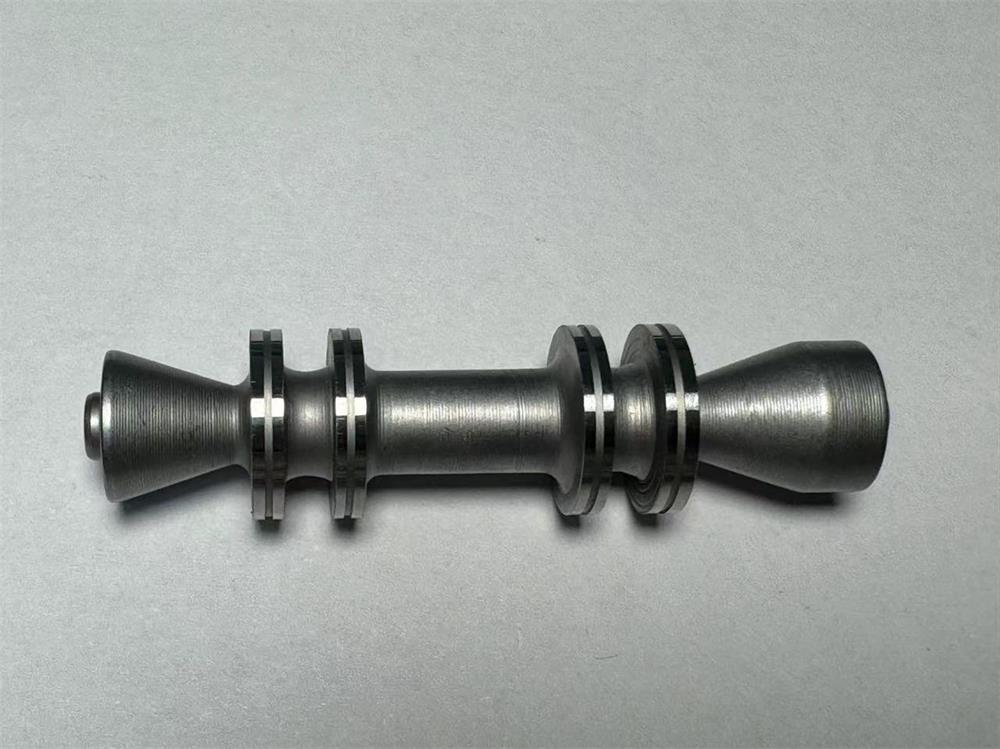

This is a kind of helicoid screw flighting with conical inner diameter and outer diameter. It is the most difficult type of helicoid screw flights to make.

Usually there are four elements in making screw spiral blades: Outer diameter, Inner diameter, Pitch and Plate Sheet Thickness. Our product parameters are all beyond the usual ranges.

This time the outer diameter and inner diameter all changes from large to small at the same time for a cone shape. This is also the most difficult process to grasp in the production work.

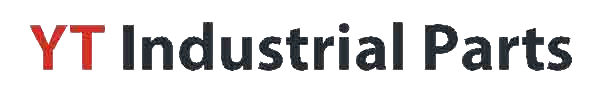

The thickness of this cold-rolled steel plate is 50 mm. This caused the processing extremely difficult. There must be no mistakes in the production process otherwise it will be impossible to make it again.

And the order quantity this time is only for one set (sample set). In order not to increase the cost of production it is necessary to ensure the success of production at one time.

Therefore all kinds of data must rely on the precise calculation by our technicians during production. Our workers’ masters rely on the recognition of the properties of materials and the control of changes in every step of the processing, then the task can be completed. Hmm. This is completely a crafted by hand.

The helicoid screw flighting spiral blades in this order is welded by three sections. In the process of production it is necessary to ensure that the rotating center of spirochetes is unified. This is another difficulty in this processing.

Our workers’ master find the center by static balance method. Make welding tooling die by himself to ensure the balance of products. Finally the one-time success of production was realized.

Congratulations!