General

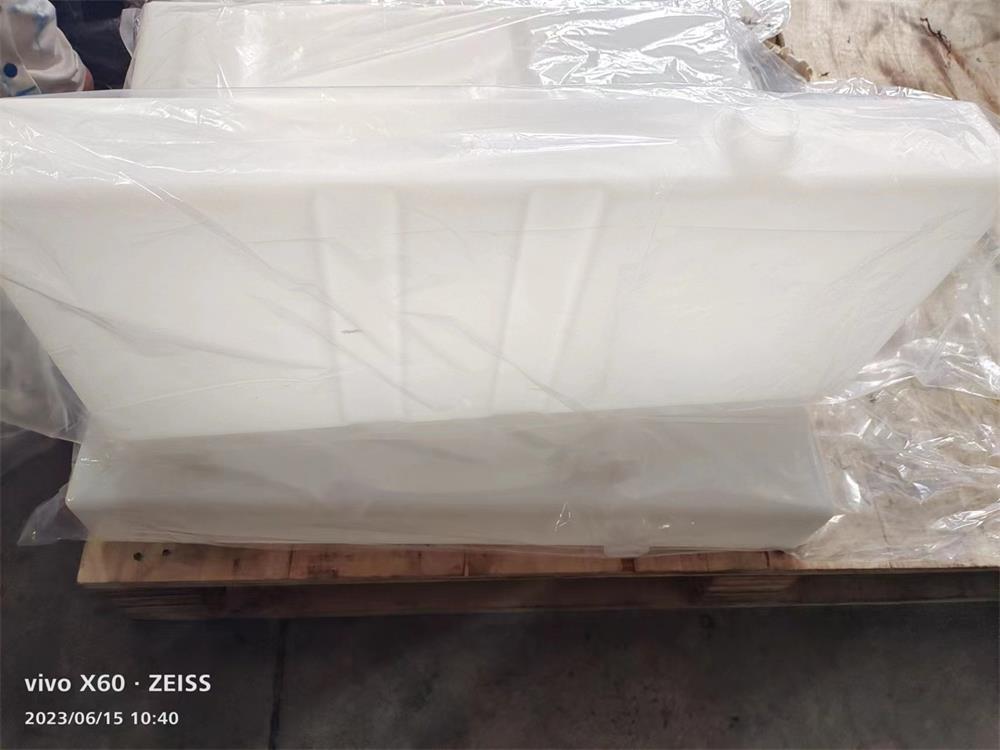

It is a new project for us, and It is ordered by our old client. They already ordered from us the ABS plastic Pan and PVC extruding profile. Our high-quality products attract our clients to order more and more projects from us.

Picture

Quantity

Two samples after making the new mould. 400pcs for batch production.

It is an urgent delivery, so we arrange 50pcs by air shipment and another 350pcs by ocean.

Material

LLDPE (Linear Low-Density Polyethylene)

It is a type of polyethylene, which is a widely used and versatile thermoplastic polymer. LLDPE is known for its unique molecular structure, which gives it different properties compared to other forms of polyethylene, such as LDPE (Low-Density Polyethylene) and HDPE (High-Density Polyethylene).

Surface

Fine sand finishing

Process

Plastic rotary molding process, also called Rotomolding plastic.

We are a high-quality factory in China to CUSTOM the rotational molding plastic parts.

Reference link: