General

It is a repeated order, every two months for one batch.

Batch Code

Here X mean 2024, F mean July

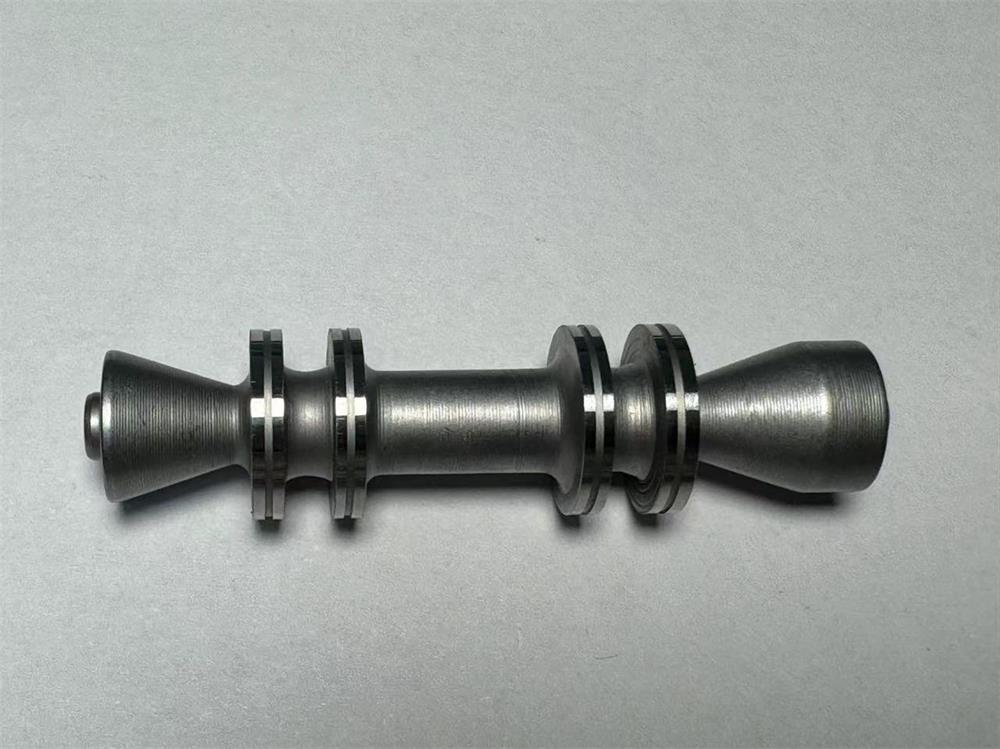

Material and Hardness

Steel 4140, hardness 38-44HRC

Surface

Dacromet Coated, anti-corrosion, anti-wear.

Protection

The dacromet coating surface is easy to be damaged, so we use a plastic net to protect it for each fastener.

Picture

What’s Dacromet coating?

Below is the explanation from AI:

Dacromet coating is a type of anti-corrosion coating commonly used on metal parts, particularly in the automotive, construction, and aerospace industries. It is a water-based coating that consists of a mixture of zinc and aluminum flakes, which are bound together by a chromium-based binder. The coating is applied through a dip-spin or spray process and then cured at high temperatures.

Key Features of Dacromet Coating:

- Corrosion Resistance: Dacromet provides excellent corrosion resistance, protecting metal surfaces from rust and environmental degradation. It is particularly effective in resisting salt spray and other harsh conditions.

- Thin and Even Coating: The coating is very thin (usually around 5 to 8 micrometers), which allows it to provide protection without significantly altering the dimensions or weight of the coated parts.

- Environmental Considerations: Dacromet is considered more environmentally friendly compared to traditional coatings because it is water-based and does not produce harmful volatile organic compounds (VOCs) during application. However, the presence of hexavalent chromium has raised environmental concerns, leading to the development of alternative coatings.

- Application Versatility: It can be applied to a wide range of metal substrates, including steel, aluminum, and iron, and is suitable for complex shapes and threaded parts.

- Heat Resistance: The coating is also known for its heat resistance, which makes it suitable for parts exposed to high temperatures.

Common Uses:

- Automotive Components: Fasteners, brake discs, and other parts that require high corrosion resistance.

- Construction: Structural components and fasteners.

- Aerospace: Parts that need to withstand harsh environmental conditions.

Due to environmental concerns related to chromium, newer coating technologies like Geomet (which is chromium-free) are being developed and used as alternatives to Dacromet.