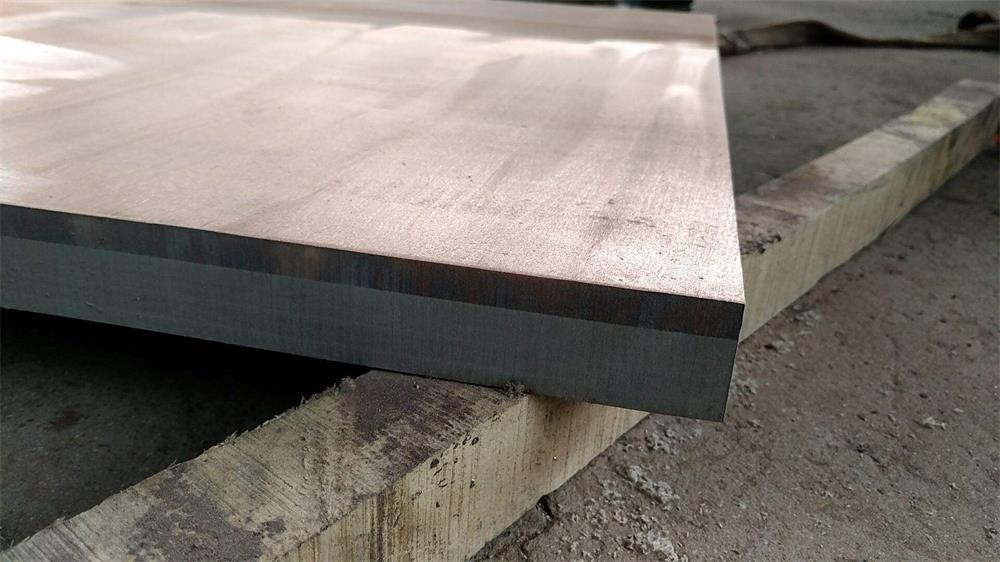

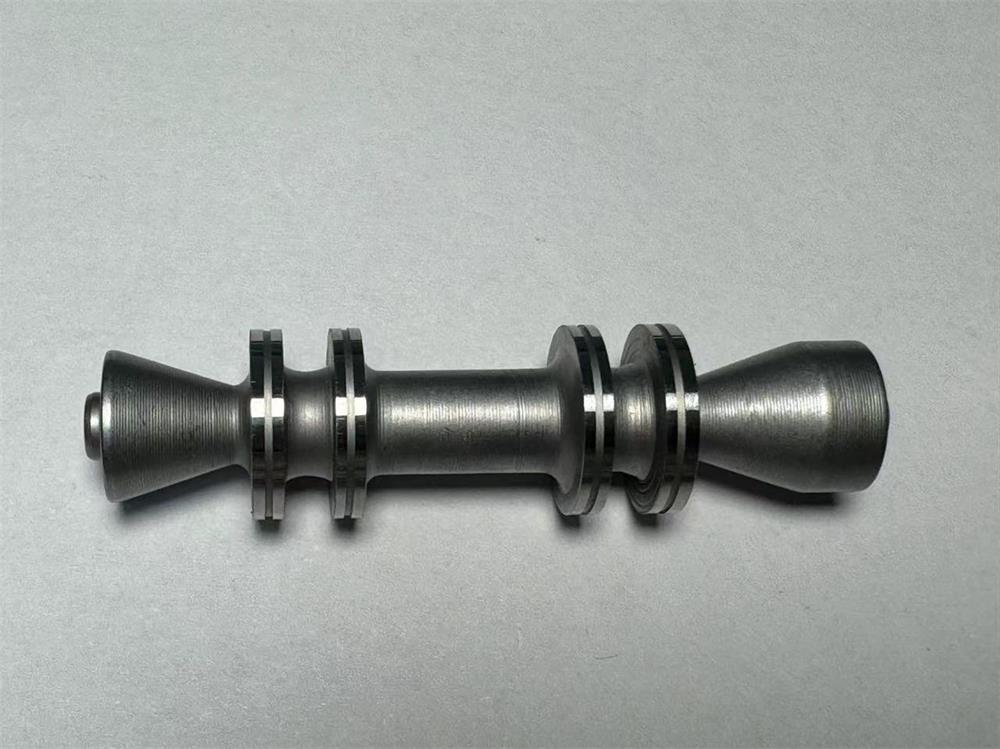

Product Pictures

Process

Cold forging + Machining, logo stamping, dacromet coating

Size

The lengths are 80mm, 89mm, 103mm and 119mm, total four specifications.

Material

Alloy Steel 4140

Heat treatment

38-44HRC

Surface

Dacromet coating, to ensure the coating quality (anti-corrosion etc.), we use NOF Metal Coating Shanghai company to make for us. This company is designated by the Dacromet.

Batch Code

This is a repeated order product, every time we will use a different batch number.

Like the attached picture, W means 2023, and G means September.

Packing

We will use a plastic net to cover the pin body, in case of any damage to the surface during the transportation.