General

After we received both the PDF and 3D drawings, we checked the material, size with tolerance etc. Evaluating the manufacturing process.

We need to stamp the Manufacturer’s Identification Symbol on the back of the product. We have determined to use YT-202410, our logo YT, plus the order time.

Process

It is the common shell casting process; we manufacture the metal mould and make the sampling first.

Express the samples to our client’s office for approval. After the sample is approved, we begin the batch production immediately.

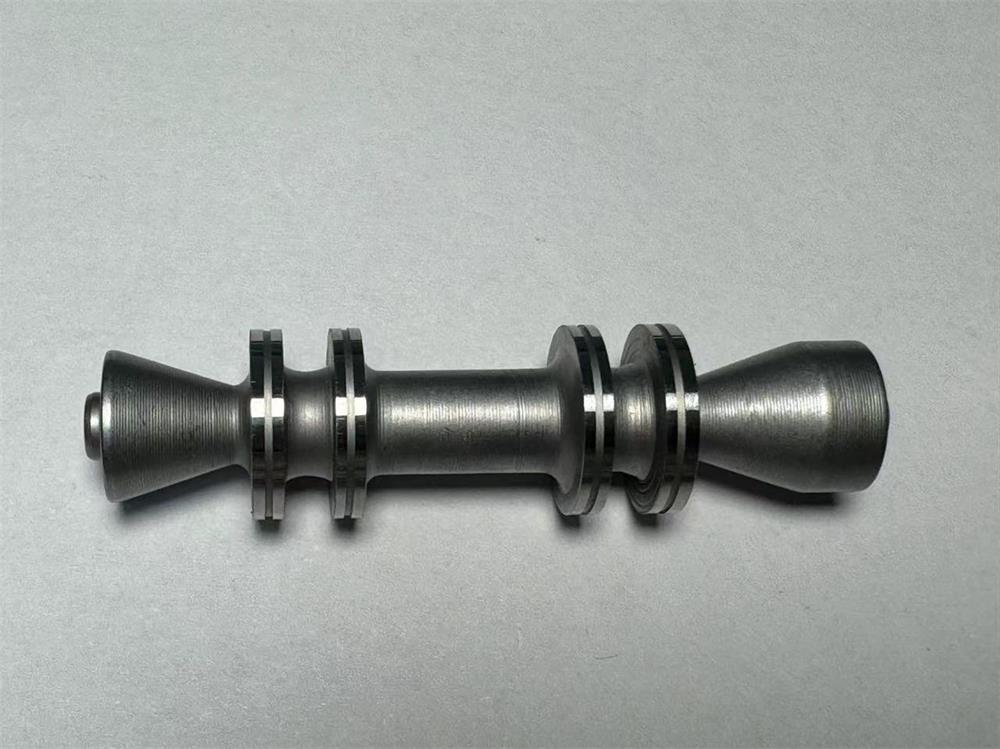

Sample pictures

Batch Quantity

275pcs

Drawing

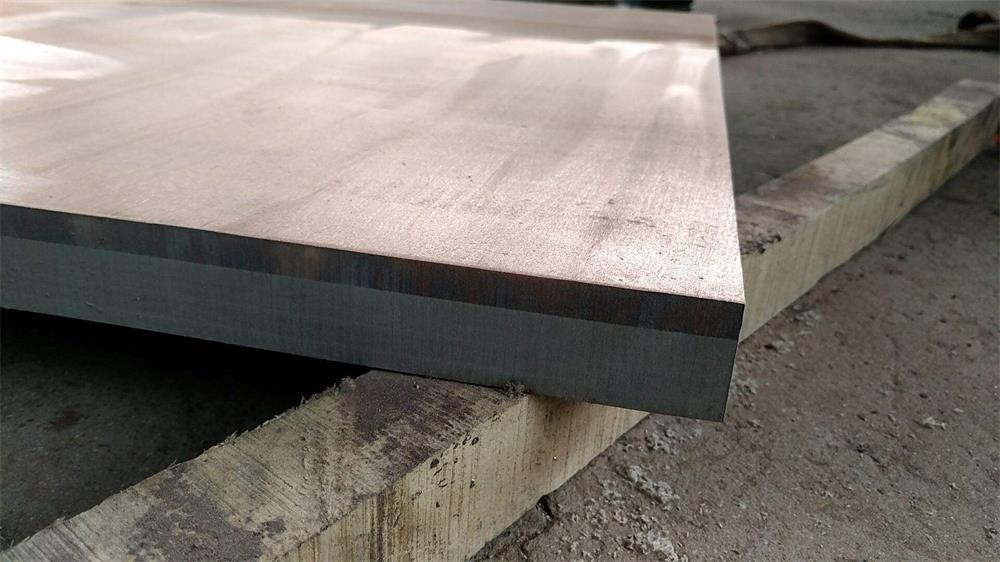

Material

Cast Iron, ASTM A48, Class 20

It is the common Cast iron, the standard is ASTM A48. We need to make sure that our material’s chemical composition and mechanical properties 100% meet the requirements of this standard.

Product Picture

After around 30 days of production (China spring festival 20 days is extra), we finished production.

Quantity Inspection

Material Certificate

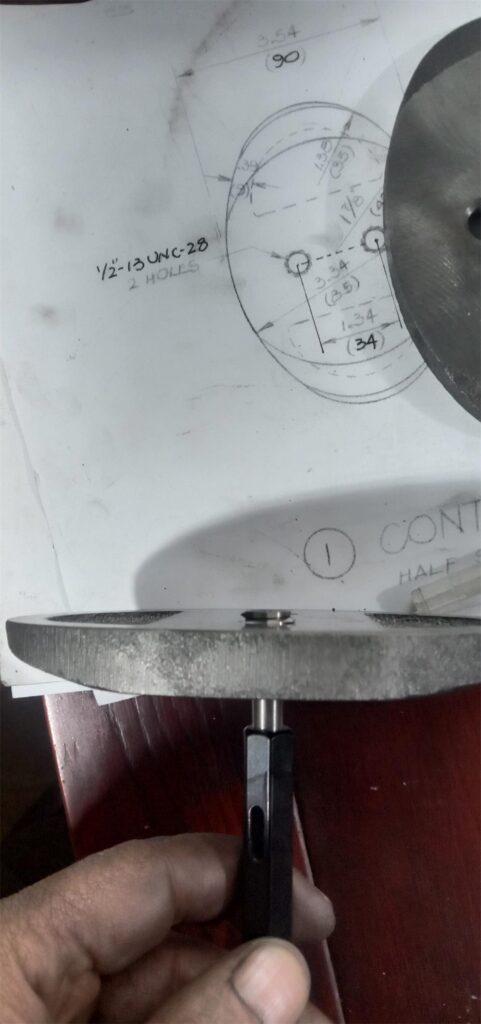

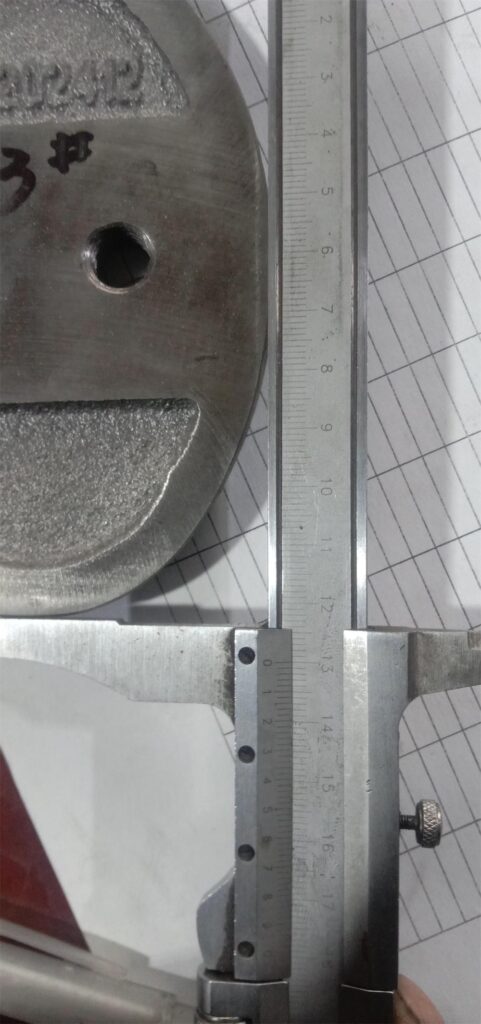

Size Certificate

We measured all the sizes in the drawing, took pictures and then sent them to our client for approval before shipment.

We marked the number of each size inside the drawing, which corresponds to each measured photo

Size Certificate

Packing

It is packed inside the non-wooden cases. We already pasted the mark and are ready for shipment.