Application

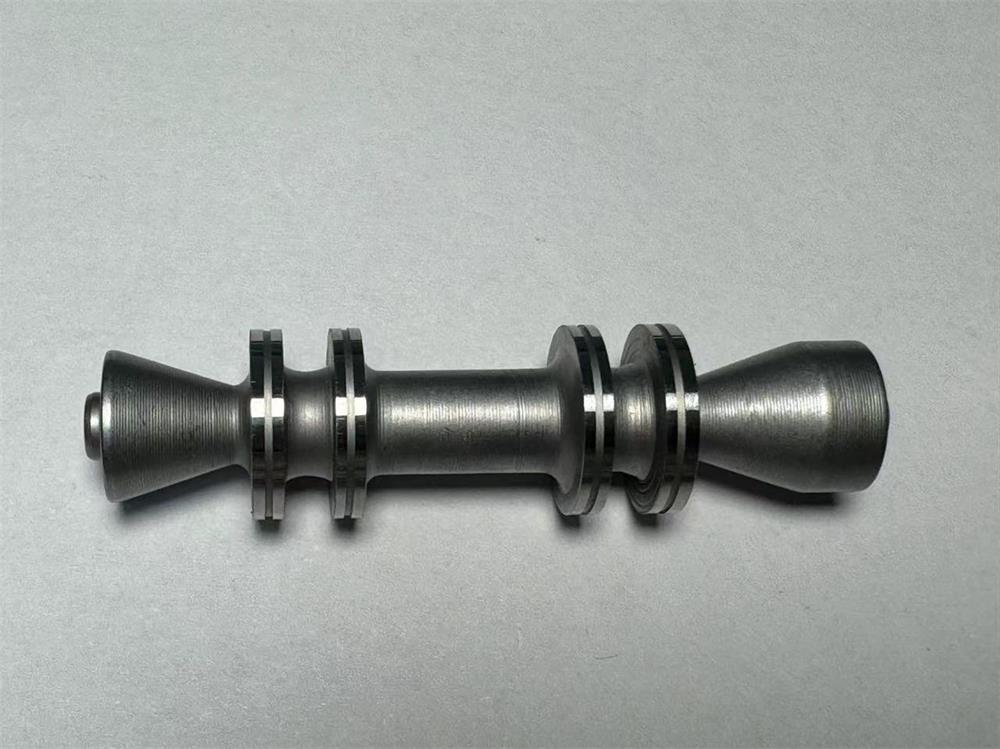

This is an order from a customer in Australia. Has been ordering from us for more than ten years. The production process is sand castings and forgings. Used in the automobile after sale maintenance market. Our good production technology and rigorous service bring them a good evaluation.

Industrial Parts Process

YT industry parts provides customized services for our customers. I know that many engineers have done the drawing design but no one can realize it. We are a very reliable manufacturer of industrial parts in China. According to different materials and different processes.

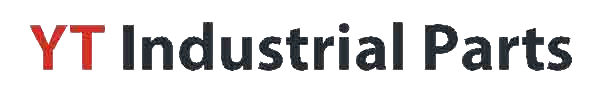

For example, metal materials are divided into stainless steel, alloy steel, anti-wear steel, Aluminium and copper etc. The processes included metal casting, forging, stamping, sintering etc.

Metal casting includes Precision investment casting, Sand shell casting, Alu. and copper casting, hydraulic valve casting.

Plastic processes include plastic injection molding and PVC Extrusion.

We also have customized service for rubber industrial products. Process has rubber compression and EPDM extrusion.

We also have needle bearing, customize bolt, pin and shaft for our clients’ assembly work.