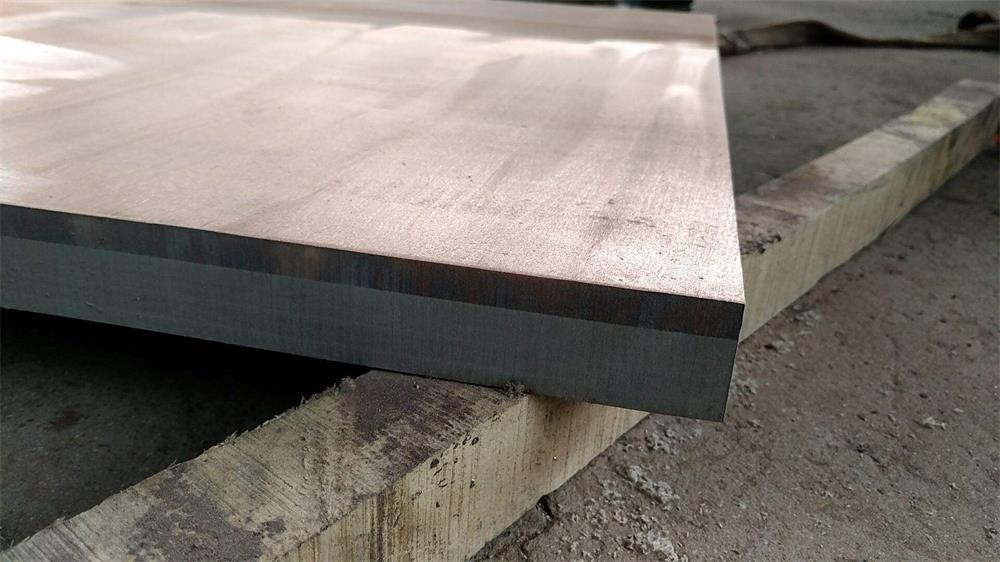

Can the Steel Plate be a Composite Structure with A36 Carbon Steel at the Bottom and Stainless Steel 316L at the Surface?

One of my clients sent me a drawing for our fabrication. The material is A36+316L, and the 316L surface material thickness should be at least