There are a few differences between the water glass casting process and the silica sol casting process in terms of chemical composition, production methods, casting effect and also the price.

Firstly, from Chemical Composition:

- The water glass casting process mainly uses water glass as the main raw material. The silica sol casting process uses silicate hydrated glass as the main raw material.

- Water glass is a combination of oxide and silica, while silica sol is a high molecular polymer formed by the condensation of silicate solution.

Secondly, the Production Methods are also different.

- The water glass casting process usually adopts the traditional sand casting method. That is, water glass and sand are mixed to form a sand mould, and then the metal solution is injected.

- The silica sol casting process uses precision casting, which uses the characteristics of silica sol to mix it with modelling materials to make a high-precision silica sol core, and then inject the metal solution.

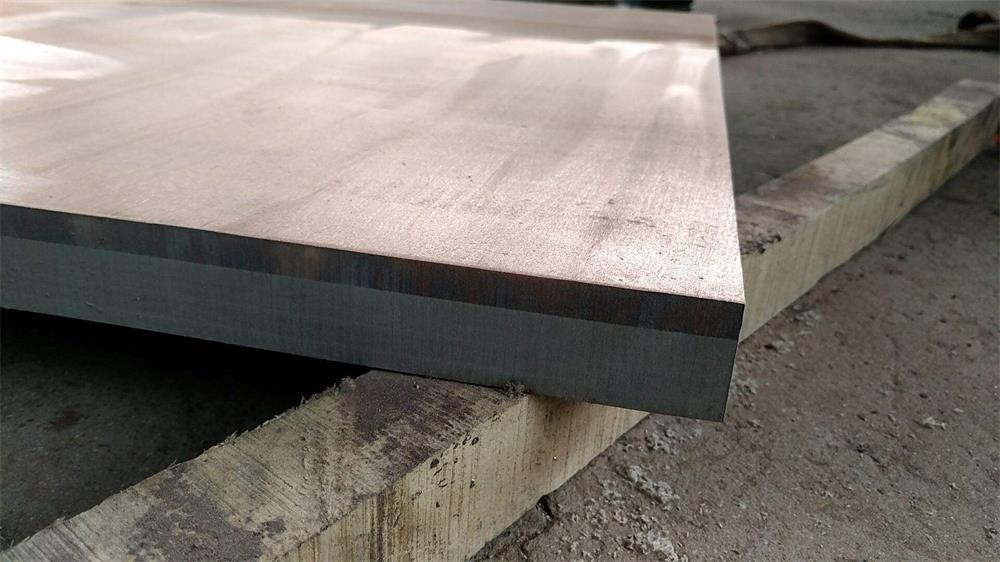

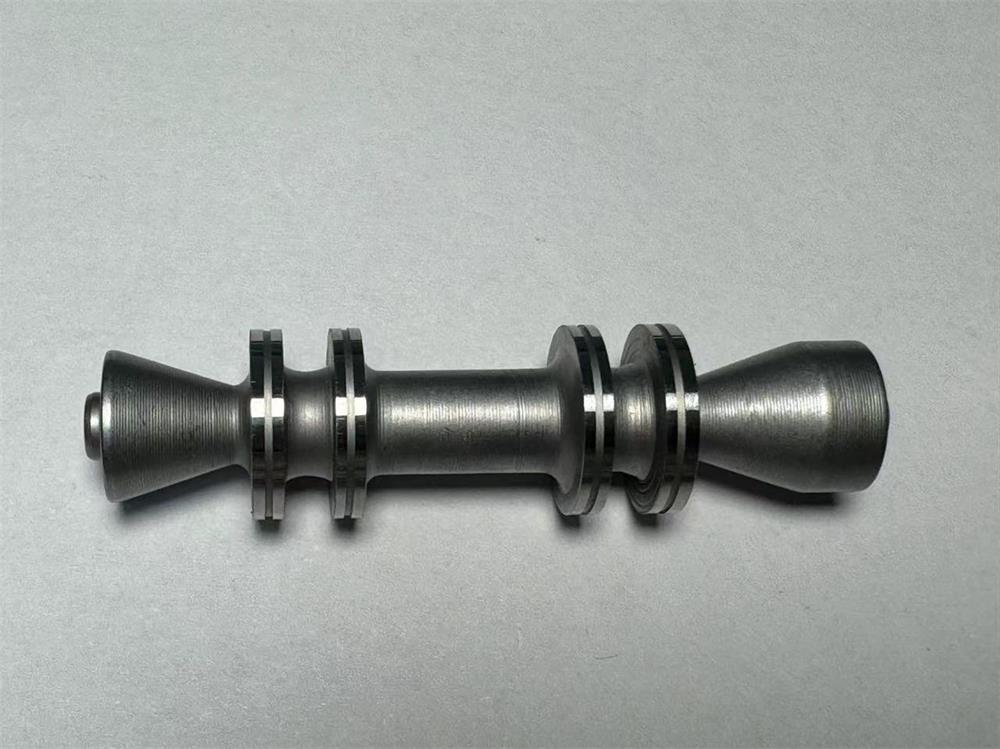

Third, Casting Effects are different.

The surface of the casting produced by the water glass casting process is rough, the precision is low. And it is easy to produce pores, sand holes and other process problems.

The silica sol process has the advantages of high precision, high smoothness, and high strength, and can produce finer and more complex castings.

Fourth, the Prices are different.

Water glass castings are less expensive.

Silica sol castings are more expensive.

There are obvious differences between the water glass casting process and the silica sol casting process in many aspects. The specific casting process to be applied needs to be determined based on the specific requirements and production conditions of the casting.