How to deal with surface defects of stainless steel castings?

In the production process,sometimes stainless steel precision casting castings will produce product defects, like sink, dents, cracks, and even rust after the long improper storage. We can use the polishing method to clean up the defects on the product. In the process of grinding, our precision castings must meet the tolerance requirements of castings’ drawing. Generally speaking, deformed castings can be corrected by mechanical methods.

How to treat the surface defects of stainless steel castings by mechanical methods?

We can directly use the welding repair method to deal with it. When the product adopts tungsten argon arc welding. The area of welding and the depth of welding must conform to its regulations. The area of welding refers to the area of after welding.

Requirements for welding repair.

Stainless steel castings can not be repaired more than three times in the same place. The distance between the welding edges of castings shall not be less than the sum of the diameters of adjacent welding area. If the precision casting is produced and supplied in a heat-treated state. After the welding repairs, it should be heat treatment.

Qualification standard after welding repair.

After heat treatment of stainless steel castings. This casting needs to be tested for mechanical properties. The area of argon arc welding zone in castings shall not be less than two square centimeters. The welding distance should be greater than 100 mm. In this case, heat treatment may not be performed. But no more than 5 places on a stainless steel casting.

The weld repair area of stainless steel castings should not have cracks and no weld penetration cases. In any welding zone the casting is allowed to have pores with a diameter of not more than two millimeters but not more than 1/3 of the wall thickness, max for three areas. The margin of the product cannot be less than 10 mm.

What stainless steel castings can’t be repaired by welding?

If stainless steel castings are used for corrosive materials. Welding flux is not allowed to be used in welding repair of products. If there is a fatal air-seal requirement for stainless steel castings, it is also not allowed to carry out penetration and leak repair treatment.

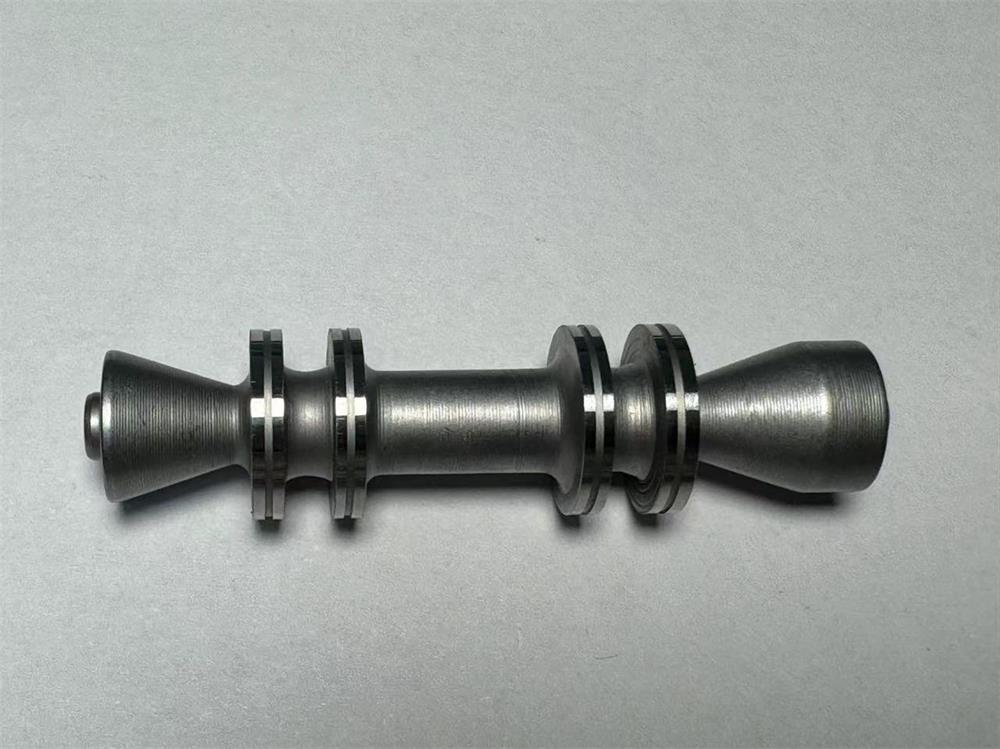

What can Yutung foundery do?

Yutung Foundry specializes in precision casting for slica sol, stainless steel precision casting, precision shell casting. We can do one-stop service from mold making, foundry, machining and final finishing to complete all processes. At present, the materials we can produce are stainless steel,anti-high temperature steel, carbon steel, mild alloy steel, non-ferrous alloy and other materials of many kinds of products.